WEIGH BATCHING SYSTEMS

Simple or Sophisticated Batch Control

Flexicon bulk bag loss-of-weight batching systems consist of a Flexicon bulk bag discharger mounted on load cells which measure weight loss of each discharger during the batching cycle and transmit the information to a system controller.

The batch sequence is initiated by a manual start button or automated signal.

As the conveyor unloads material at maximum feed rate, the load cells transmit loss-of-weight information to the controller which reduces the feed rate to dribble immediately prior to stopping the flexible screw conveyor or rotary airlock valve once the target batch weight has been discharged. System software permits mid-batch bag changes.

Multiple weigh batch dischargers can each convey a different ingredient to a central discharge point such as a hopper, blender, reactor, or other process equipment.

Whether you require loss-of-weight bulk bag weigh batching units or complete gain-in-weight batching systems, Flexicon offers the in-depth experience, the range of efficient products, and the technical field support you need for guaranteed weigh batching and blending results.

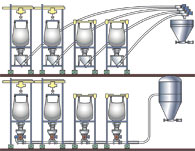

Flexicon mechanical (top) and pneumatic (bottom) loss-of-weight batching systems transport material from one or more bulk bags to a common hopper, blender, conveyor, shipping container, or any process vessel.

Loss-of-Weight Batching Systems discharge one or more bulk bags while weighing the material and conveying the batch directly to a common hopper, blender, conveyor, shipping container, or any process vessel—automatically and accurately. Load cells transmit the amount of weight lost to a controller, which stops the conveyor once the target batch weight has been reached.