Click to enlarge

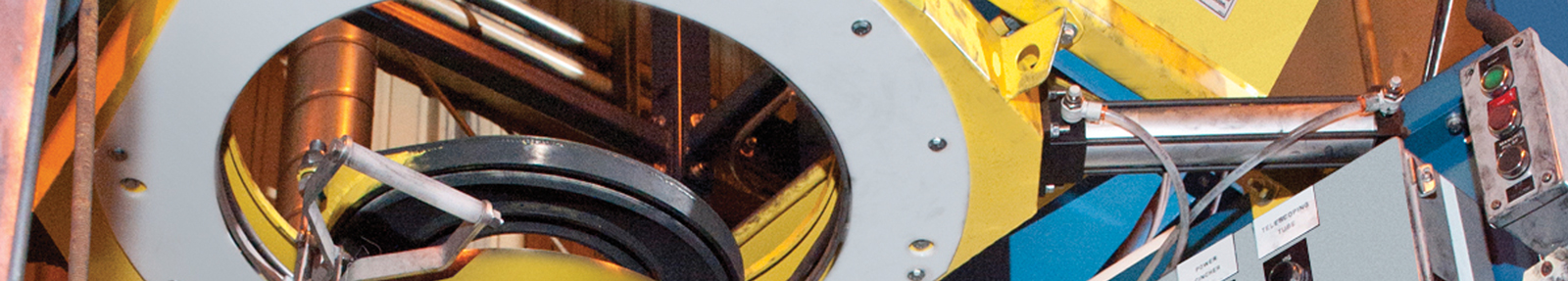

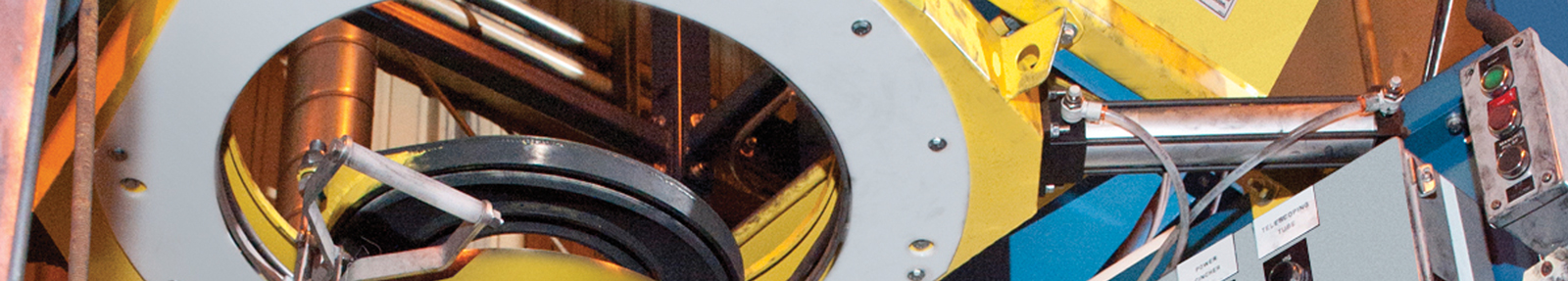

Click to enlargeThe bulk bag discharger, hopper and flexible screw conveyor from Flexicon fully contain carbon black pellets, preventing dust from entering the plant environment. A SPOUT-LOCK® clamp ring forms a sealed connection between the bag spout and the TELE-TUBE® telescoping tube, which keeps the bag taut as it empties/elongates, promoting discharge. The sealed system is vented through the black hose to a BAG-VAC® dust collector that contains displaced dust and collapses empty bags, eliminating dust caused when bags are flattened manually.

Click to enlarge

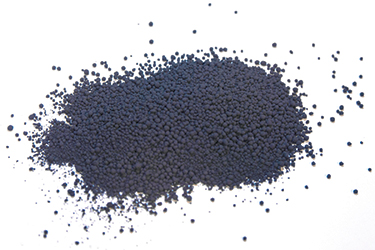

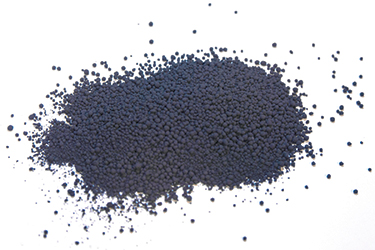

Click to enlargeKirkhill-TA receives carbon black in bulk bags to minimize inventories. Carbon black imparts important properties to the elastomers that Kirkhill-TA manufactures.

Click to enlarge

Click to enlargeDust is created as 1-3 mm diameter carbon black pellets rub together.

Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge Click to enlarge

Click to enlarge